It is mainly used for uniformity testing and transmittance testing of automotive LCD displays at room temperature.

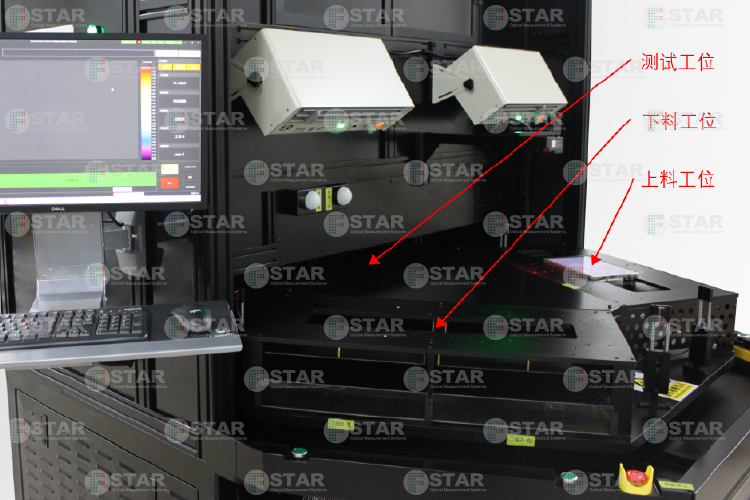

It is equipped with three testing stations: loading station, measurement station, and unloading station. Depending on the layout of the production line, it can adopt a single-operator mode or dual-operator mode. In single-operator mode, both loading and unloading are completed at the unloading station. Depending on the product, it can perform single-screen testing or dual-screen testing.

For production line operations, 3 pairs of through-beam gratings are added to ensure personnel safety. When the gratings are triggered, press the alarm reset button, then press "continue measurement" to resume testing.

The barcode scanner is equipped with a flash and buzzer to facilitate scanning by operators.

After setup is completed, press the start button with both hands to initiate the test.

Additional indicator lights for test results and data upload are added to help operators track product OK/NG status, production output, TT records, and product posting.

{{data.abstract || "No product introduction available"}}