Spectrometer-Based OLED Microdisplay Module and Device Lifetime Testing System

It is compatible with lifetime decay testing of multiple OLED microdisplay modules and devices. The software performs automatic positioning via CCD photography and reads luminance, chromaticity, and other data for each station through a spectroradiometer. During testing, the software backs up test data in real time and supports on-demand export of test reports.

※ Module products are tested by lighting via a signal generator. During testing, corresponding aging images can be set, and test points and test images can be freely configured.

※ Semi-finished products are powered and lit via Fushida's independently developed multi-channel power supply module. During testing, voltage and current for each station are read and recorded.

System Composition

- Fully enclosed darkroom (with 3-axis motion control system)

- Spectroradiometer

- Visual positioning system

- Microdisplay module room-temperature fixtures

- Device room-temperature fixtures

- Device high-temperature fixtures (independent temperature control, range: room temperature ~ 100℃, accuracy: ±1℃)

- Infrared temperature measurement system (real-time monitoring of product temperature, accuracy ≤ ±5℃)

- Module channel signal board and microdisplay communication interface

- Digital multimeter (range: 1mV ±0.05% full scale, 1pA ±0.05%)

- UPS uninterruptible power supply (saves data during power outage; UPS operating time > 15min)

- OLED lifetime testing software

- Industrial computer

System Features

Spectroradiometer: Used for testing optical parameters, including luminance, chromaticity, color temperature, emission spectrum, etc.

Alignment CCD: Equipped with a 5-megapixel industrial CCD. Before testing, it automatically identifies the position and center point of the light-emitting surface via photography, and the instrument moves directly to the corresponding position for testing.

Infrared thermometer: Measures the temperature of modules and wafer surfaces via infrared. After each luminance test, the temperature at the same position is read.

Screen Lighting Tester:

① 6 channels with 0-10V, 0-300mA output; 2 channels with -10~0V, 0-100mA output

② 2 groups of 12V power input

③ 10-channel voltage measurement with accuracy of 1mV ±0.05%; 10-channel current measurement with accuracy of 1pA ±0.05%

④ 2 microdisplay communication interfaces

⑤ 1 tester can light 2 microdisplays.

Sample lighting method: Each sample has 14 pads, each powered by direct current (DC).

Lighting modes: Constant current, constant voltage, or pulsed current/voltage testing. The duty cycle of pulsed current or voltage can be adjusted within 1-99%.

Software Functions

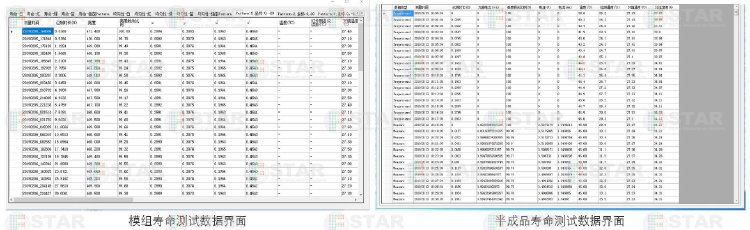

Module Product Testing

- Grouped testing: Different groups can be configured with different test items and parameters, and each group can start and stop independently.

- Lifetime test time intervals and interval settings: Three time intervals and test intervals can be set.

- Lifetime test termination condition judgment: Measurement stops when luminance decays to a specified percentage of the initial value, or according to the total time set by the user.

- Automatic identification of OLED placement position: Select the test station on the software, and the software controls the industrial visual alignment CCD to automatically scan the size and center position of the OLED light-emitting area at the test station.

- Lifetime prediction function: The software has a built-in lifetime prediction formula, which automatically calculates the estimated lifetime based on real-time measured data.

- Real-time saving and recovery of measured data: The software saves data in real time during testing. If the computer shuts down abnormally or the software exits unexpectedly, previous data can still be loaded and measurement can resume after restarting.

- Aging image setting: The software can set a group of aging images, and the OLED cycles through these images during the waiting period between tests.

- Barcode scanning support and data upload to server (upload protocol to be provided by the customer).

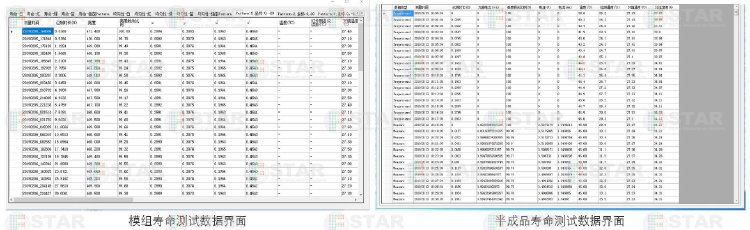

Semi-Finished Product Testing

- For each device product, the power output mode, luminance sampling interval, and measurement termination conditions can be set separately. Each channel can start and stop measurement independently.

- At the start, end, or during testing, one or more stations can be set for IVL testing. Both the configuration and number of IVL tests can be set via the software.

- Measured data includes: elapsed measurement time, current luminance ratio, current voltage/current values, and estimated lifetime. Data for each OLED is automatically measured, recorded, and plotted into a luminance decay curve. Even in case of measurement abnormalities, after restarting the computer or software, data before the abnormality can be automatically loaded to resume measurement.

Software Interface